Add to Cart

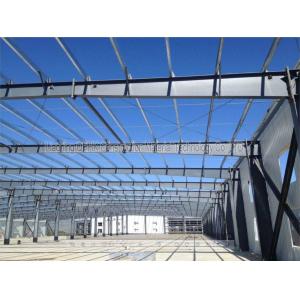

Sandwich Panel Prefab Workshop Steel Structure With USA Standard Welding

STEEL WORKSHOP

Applications

Factories | Commercial | Trade Centers | Warehouses | workshop | Cold stores | Showrooms | Schools | Hospitals | Pump stations | Residential barracks Offices | High-rise Buildings

PROJECT CASES

Prefab Steel food warehouse for Ghana.

Project size:16538.80Sqm

Steel Structure Quantity: 496.2tons

Dead Loading:0.4KN/m2

Live loading:0.5KN/m2

Wind load: 0.45kn/m2

Project size:7062.90Sqm

Steel Structure Quantity: 277.9tons

Dead Loading:0.3KN/m2

Live loading:0.5KN/m2

Wind load: 0.55kn/m2

PRODUCT DESCRIPTION

| Main frame steel | Steel Welded H Section or hot rolled H section |

| Purlin | C or Z Section Channel for roof and wall |

| Cladding system | Sandwich Panel or Corrugated Steel Sheet with Fiber Glass Wool for wall and roof |

| Tie Rod | Circular Steel Tube |

| Brace | Round Bar |

| Column & Transverse | Angle Steel or H Section Steel or Steel Pipe |

| Knee Brace | Angle Steel |

| Roof Gutter | Color Steel Sheet |

| Rainspout | PVC Pipe |

| Door | Sliding Sandwich Panel Door or Metal Door |

| Windows | PVC/Plastic Steel/Aluminum Alloy Window |

| Connecting | High Strength Bolts |

| Main steel material | Q345, Q235, Q345B, Q235B,Q355 etc |

| Packing | Decided by you , loaded into 1X 40ft GP,1X20 ft GP,1X40 ft HQ |

| Drawing | We can make the design and quotation according to your require or you |

| Crane | Decided by you |

WE CAN PROVIDE

1. Customized design will be provide with free

We can design complex industrial building for clients by using AutoCAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures (Xsteel) and etc.

2. Steel Structure Building Manufacturing Process:

3. We have many production lines and strong production capacity as follows:

2 fabrication factory tatol area 18000 Sqm!

5 heavy steel structure production lines!

1 assembly workshop that can assembly steel bridge!

Production capacity of steel structure components: 50000 tons per year

Total area of finished steel structure projects: 17600000 m2

We have enough strong production space and production capacity to delivery the goods on time.

4. Quality control.

General fabrication main process of steel structure is divided into: material preparation →cutting→ assembling→ welding→ drilling → assembly → correction → shot blasting and rust removal → painting → number →component acceptance ex-factory. In the steel structure production, according to the steel structure production process flow, grasp the key processes for quality control, such as control of key parts processing, main components of the process, measures, processing equipment, process equipment, etc. Each processing part, we can have strict inspection specifications. Welding engineering is the most important link in steel structure fabrication and installation engineering. For the welding,

We have our qualified CWI welding inspector to control the quality according to AWS-D1.1/D1.5 welding quality system. Spot welding strictly weld according to AWS welding quality system.

ATTEND EXHIBITION

CUSTOMER VISIT

GET THE BEST PREICE

Please kindly inform us information as below if you are interested our products.

Such as these questions:

1. Usage: _____ for warehouse,workshop, showroom etc.

2. Location (where will be built? ) _____country, area

3. Size: Length*width*height _____mm*_____mm*_____mm

4. Wind load (max. Wind speed) _____kn/m2, _____km/h, _____m/s

5. Snow load (max. Snow height)_____kn/m2, _____mm

6. Anti-earthquake _____level

7. Brick wall needed or not If yes, 1.2m high or 1.5m high

8. Thermal insulation

If yes, EPS, fiberglass wool, rock wool, PU sandwich panels will be suggested;

If not, the metal steel sheets will be OK.

The cost of the latter will be much lower than that of the former.

9. Door quantity & size _____units, _____(width)mm*_____(height)mm

10. Window quantity & size _____units, _____(width)mm*_____(height)mm

11. Crane needed or not If yes, _____units, max. Lifting weight____tons;

Max. Lifting height _____m.

FAQ

Q1: Can I have a visit to your factory before the order?

A: Why not? Welcome to visit our factory. You can fly to Shenyang Taoxian Airport, then we will pick you up at the airport, hotel booking service is available.

Q2: Do you supply installation service?

A: Yes, we do. But you will pay for our professional installation cost at your local place, then we will send the engineers to supervise it.

Q3: How long can the frame be used?

A: The use life of the main structure is the designed used life, usually is 50-100 years (standard request of GB)

Q4: How long is the use life of the roof cover?

A: The use life of the PE coating is usually 10-25 years. The use life of roof sun light sheet is shorter, usually 8-15 years

Q5: What is the anti-rust treatment for steel structure?

A:Anti-rust treatment of steel structure

Normal anti-rust paint

Anti-rust paint with epoxy zinc primer

Hot-dip galvanization

Hop-dip galvanization + PU finish

Powder coating

Stainless steel structure: No. 301/304/316 stainless steel structure

Q6: How do we cooperate on certain project?

A: Firstly, please send us your project details and your requirements. Then we will design accordingly, free of charge. Afterwards, please check and confirm whether you like the drawings. If not, we shall get the drawings revised until your confirmation. Finally we make a deal.